|

|

| TAKACHIHO Germanium Quality and Hardening / Photo catalyst processing |

In-plant processing pure germanium In-plant processing pure germanium |

|

Our products are made from 99.99% germanium ingot and processing it into the finished

Germanium grain products as 99.98%~99.992%purity.

Basic 3 types:

・Conic shape (GK series):

Hard type with comfortable reaction to your acupressure points

・Dome shape (GS series):

Soft type to fit your skin

・Hemispherical shape (GH series):

Regular type with round shape, kind to your skin

These 3 products are selected by your required purpose and usage.

Your specific requirements are available to make.

|

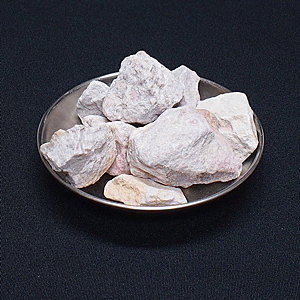

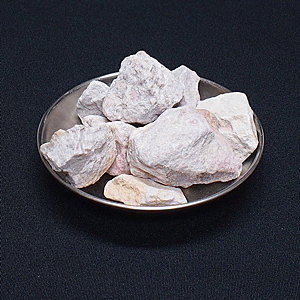

| Processing flow to manufacture Germanium grain products: 1 Germanium Ore |

|

Containing trace amounts of germanium inside, with colors as pale pink or skin color and gray.

Some germanium bracelet in the marketplace are made from these original germanium ore.

Main suppliers are from Russia and China as country of origin. |

| 2 Germanium Ingot |

|

Purified germanium ingot is processed by using trace amount of raw material of germanium ore.

TAKACHIHO METAL selects purity imported material and only uses 99.999% ingot, certified with independent analysis authority.

|

| 3 Crushing the Ingot into pebbles |

|

First, the ingot is crushing into pebbles.

High purity five nines (99.999% purity) with beautiful platinum color.

|

| 4 Crushing into powders |

|

Then, the ingot pebbles are grinding down to fine particle powders.

And, in non-oxidizing furnace of a high temperature of 1000 ℃ plus, the germanium powders are fully-sintered according to several particle size.

This production process is used our own technology developed in 2001.

Of course, no other materials are added during this process.

|

| 5 Finished products: |

|

After the non-oxidizing furnace processing, the germanium grains are finishing to polish the surface and bottom and inspection.

Conic shape (GK series): Hard type with comfortable reaction to your acupressure points

The shape is considered from acupressure effect of oriental medicine.

Bigger sizes are for using pasting. |

| Dome shape, soft type with gentle curve |

|

By increasing the contact area to your skin, this dome shape may hold the germanium reactions to your body temperature.

Good for necklaces or bracelets.

|

| Hemispherical shape (GH series): Regular type with round shape, kind to your skin |

|

This is regular type of hemispherical shape.

This shape gives you soft and gentle contact to your skin, using for several usage including bracelets. |

Qualified Products rcommended by Noguchi Medical Research Institute, USA Qualified Products rcommended by Noguchi Medical Research Institute, USA |

|

TAKACHIHO's Germanium Grains and PEAK PINE Brand Products quality is recommended by Noguchi Medical Research Institute, contributing to international medical exchanges. |

Pure titanium body and germanium grains Pure titanium body and germanium grains |

Our PEAK PINE brand products are with body material made of pure titanium, which is biocompatible and healthy material. Also, non-allergy and anti-corrode. Check the quality in back side of our products.

Germanium grains also keeps quality of the accessory attaching to donut-shaped pure titanium parts which also function to avoid falling off or missing |

|

Hardening processing Hardening processing |

This processing protects your accessories from surface damages.

Hardening processing always gives you same gloss as first bought, without any damage to the surface quality, same technology applied to the surface treatment of medical devices and cameras.

Comparison test data under 90 days normal wearing

Upper photo: with the hardening processing product

Lower photo: without the hardening processing product

(By lighting, you can find small damages)

Hardening processing makes the surface hardness as 8 or 10 times harder, to protect your accessories from fine and small surface damages

Note: This hardening process is applied to the production since October, 2014. |

|

Photo catalyst processing Photo catalyst processing |

Do you know a photo catalyst?

It creates active oxygen which works for harmless and safe-friendly natural light.

Using photo catalytic semiconductor metal (titanium oxide) as a catalyst, the active oxygen is created by removing impurities from water and oxygen in the air (organic compounds).

Due to its nature of strong oxidation reducing power, it effects to antibacterial, sterilization and allergy-stain, deodorant, purification, rust as well.

Useful function of this light energy is used for our germanium products. |

|

Effect and merit the photo catalyst Effect and merit the photo catalyst |

① Healthy effects available by antimicrobial action.

② Hard to get stain by antifouling action.

③ Easing the discoloration speed of the product.

④ May free from metal allergy (depending on individual)

⑤ Due to clear coat (transparent), mirror finish available by processing without affecting color shade of the material.

⑥ Available to apply to any materials such as titanium, stainless steel, gold, silver, platinum by room temperature processing.

⑦ During processing, no damages to accessories and precious metal ornaments with diamonds

Our nanotechnology of the light coat is the processing method to penetrate the fine particle titanium oxide on the material surface. |

|

|

COPYRIGHT(C)2006-15 Germanium chip Takachiho Metals Co., Ltd. ALL RIGHTS RESERVED.

|

|